For truck fleets, downtime isn’t an option. To stay on schedule and keep the rubber on the road, your fleet management strategy must focus on managing efficiencies and leveraging data.

Truck Fleet Management Solutions

From small Class 1 light-duty to large Class 8 big rigs, truck fleets often manage the deliveries of time-sensitive materials, so ensuring your assets are in good condition is critical.

That said, many truck fleets struggle with downtime, because their fleet is spread out across long distances, and breakdowns can occur at any moment—especially without a proper maintenance plan.

To prevent unplanned breakdowns and keep up with maintenance tasks, it’s important to have an easy, comprehensive way to track and manage your truck fleet.

Fleet management software provides you with the tools to manage every aspect of your fleet, from maintenance and inspections to driver management and cost analysis.

Being able to track your fleet data in a centralized software allows you to make informed decisions regarding fleet expenses and develop strategies to set you up for success.

Below, we’ve compiled a few best practices to implement into your truck fleet management strategy to set your team up for success.

1. Keep Up with Preventive Maintenance Tasks

The first step to avoiding downtime is to ensure your trucks are properly maintained and on a regular servicing schedule. Sometimes, simple service tasks like oil changes and tire rotations are missed for long periods of time, which can ultimately lead to costly repairs.

To keep up with regular service tasks, it’s important to implement a preventive maintenance (PM) schedule to keep track of regular maintenance, maximize vehicle lifespan and prevent downtime.

With fleet management software, you can set mobile reminders based on meter readings and driving time intervals to ensure your trucks never miss regular servicing. You can also set due soon thresholds and forecast future maintenance based on fleet data.

PM schedules can be managed for both in-house and outsourced maintenance. In-house maintenance technicians can begin repairs quickly when you streamline work orders through software. This keeps you in constant communication with your team and allows you to easily track repairs and manage vehicle status.

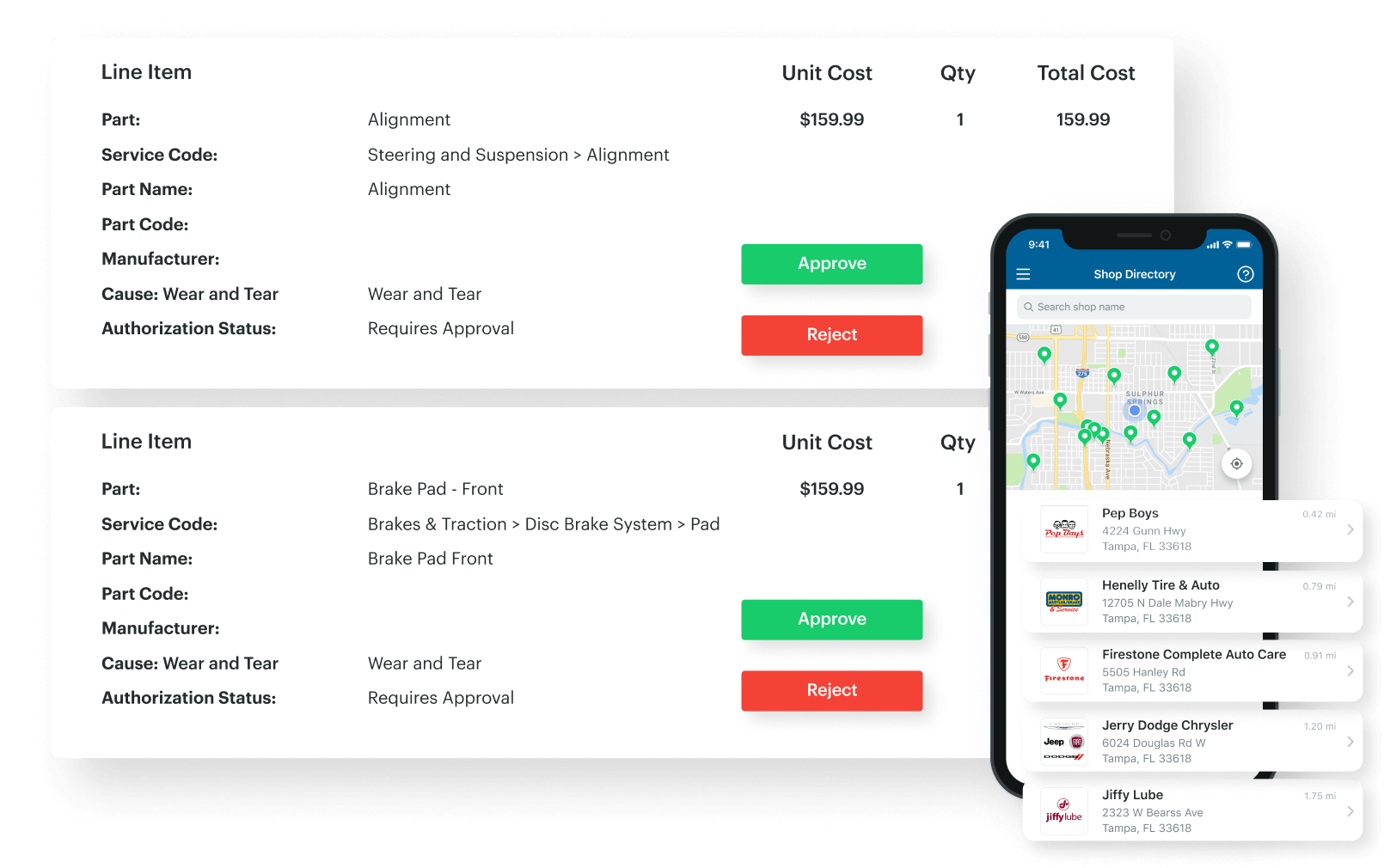

If you outsource your maintenance like many other truck fleets, automating maintenance management allows you to manage repair orders, set automatic approvals and get your vehicles back on the road faster.

2. Maintain Compliance with DVIR

Daily Vehicle Inspection Reports (DVIR) are required to stay compliant with Department of Transportation (DOT) regulations. In addition to compliance, regular inspections uncover issues and pass information to fleet managers to begin the maintenance process.

Many truck fleets are still using paper DVIR, which can cause delays in the maintenance process. Paper inspections are time-consuming for drivers, and the results are often misplaced, causing further delays.

When you have assets all across the country, it’s important to receive inspection results quickly. Electronic DVIR (eDVIR) allows drivers a quick and easy way to perform inspections on a mobile app and instantly upload results into your fleet management software.

eDVIR will automatically report issues to inform you what vehicles need immediate attention. Streamlining issue management ensures your trucks get the repairs they need quickly to reduce downtime in the shop.

3. Monitor Fuel Usage with Fleet Fuel Cards

Trucks are quite the gas-guzzlers, and fuel is the largest on-going expense for any fleet. Being able to track fuel costs easily is one of the best ways to manage costs.

Unfortunately, many truck fleets are still trying to keep up with paper receipts and manually enter fuel data.

Integrating fleet fuel cards with fleet management software is a great way to easily access all fuel data in a centralized location. Track cost-per-mile and odometer readings in real-time and get a look at your overall fuel spending.

Another major benefit of fuel card integration is the ability to control fuel expenses and prevent fraud. Set driver limits and restrictions to ensure your drivers don’t overspend.

Connecting your fuel card to your fleet management software provides you with up-to-date data by downloading all transactions daily. This quick access to data reduces the risk of overlooking critical issues and discrepancies for weeks or months at a time.

4. Capture Vehicle Data with Telematics

Maintaining visibility of your assets can be difficult, much more so when your trucks are spread out across the country.

To efficiently track your drivers and receive updates on your assets, consider integrating your telematics device into your truck fleet management software. This information can provide you with crucial insight into the safety and compliance of your drivers and assets.

Telematics integration also allows you to receive accurate and instant odometer readings and diagnostic trouble codes. Staying informed of asset health ensures you can act quickly if issues arise.

5. Calculate Total Cost of Ownership

Controlling expenses is an ongoing challenge for fleet managers. Truck fleets are some of the most expensive of all fleets, and understanding your true total cost of ownership (TCO) is crucial to the success of your fleet.

Knowing your fleet’s TCO gives you insight into fleet trends and helps you track expenses to make data-driven decisions regarding your fleet. Many fleet managers and owners have a difficult time manually tracking TCO, which can lead to missed opportunities and unnecessary expenses.

Fleet management software automatically calculates your fleet’s TCO by compiling fleet data into easy-to-read reports, eliminating the headache of number-crunching.

Determining your truck fleet’s total cost of ownership is one of the best ways to understand your overall fleet operations and ensures you are making the best decisions for the future of your truck fleet.

Hammer down your truck maintenance strategy and reduce downtime with Fleetio! Request a demo or start a free trial today.