Farm equipment maintenance management is critical to ensuring uptime and keeping up with agriculture demand. Leveraging software to manage agricultural equipment allows you to proactively manage maintenance and maximize equipment lifespan.

Building an Effective Farm Equipment Maintenance Management Plan

Agriculture is the backbone of our society, so having an effective farm equipment maintenance management strategy is essential. Without properly functioning assets, your team can’t effectively tend and harvest crops or care for livestock.

Keeping up with maintenance tasks can be difficult for farmers. Not only are they on a tight schedule, but many still use notebooks and whiteboards to keep up with maintenance.

Some farms use fleet management companies (FMC) to manage their assets. While FMCs can manage equipment maintenance, they don’t provide complete visibility into your fleet’s data. They also don’t provide a software solution that allows you to manage maintenance and stay connected to your team.

Antiquated solutions like these are inefficient, unorganized and often cause you to fall behind on maintenance tasks. In an industry that’s so heavily relied upon, farmers need a simple solution to manage maintenance and avoid downtime.

Farm equipment management software can be an easy-to-use, mobile-friendly tool that enables you to keep up with maintenance schedules and collaborate with your team. With comprehensive visibility into operations, you can understand the health of your fleet and proactively manage maintenance.

1. Take A Proactive Approach to Farm Equipment Maintenance

Farmers are responsible for a variety of equipment. From heavy machinery, like tractors and combines, to smaller equipment like tillers and cultivators, every piece of equipment is essential to your operation.

Due to the expensive nature of farm equipment, you often don’t have a back-up option when equipment is broken. To avoid unplanned downtime, it’s important to take a proactive approach to farm equipment maintenance management.

What does that mean, though? For starters, you need a solution to monitor farm asset health and manage maintenance from anywhere. Most farms are spread out across hundreds or thousands of acres. When issues occur, you need to know about them immediately and act fast.

Leveraging farm equipment maintenance software allows you to monitor all of your assets in a centralized system, regardless of your location. You can view information at a glance in your configurable dashboard or dive deep into particular areas, like work order progress and open issues.

Managing all of your fleet’s data in an easy-to-use software allows you to easily efficiently track maintenance and stay connected to your team. Teams can stay connected and update you from the field via a mobile app, allowing you to view updates in real time and proactively manage issues.

2. Create Service Reminders for Preventive Maintenance Tasks

One of the best ways to proactively manage your agriculture equipment is to stay on top of preventive maintenance. Taking time out of your team’s schedule to make small repairs helps you avoid downtime and maximize asset lifespan.

Keeping up with preventive maintenance can be difficult if you’re using calendars or messy whiteboards. Repairs are often overlooked for weeks or months at a time, which can cause seemingly small issues to compound.

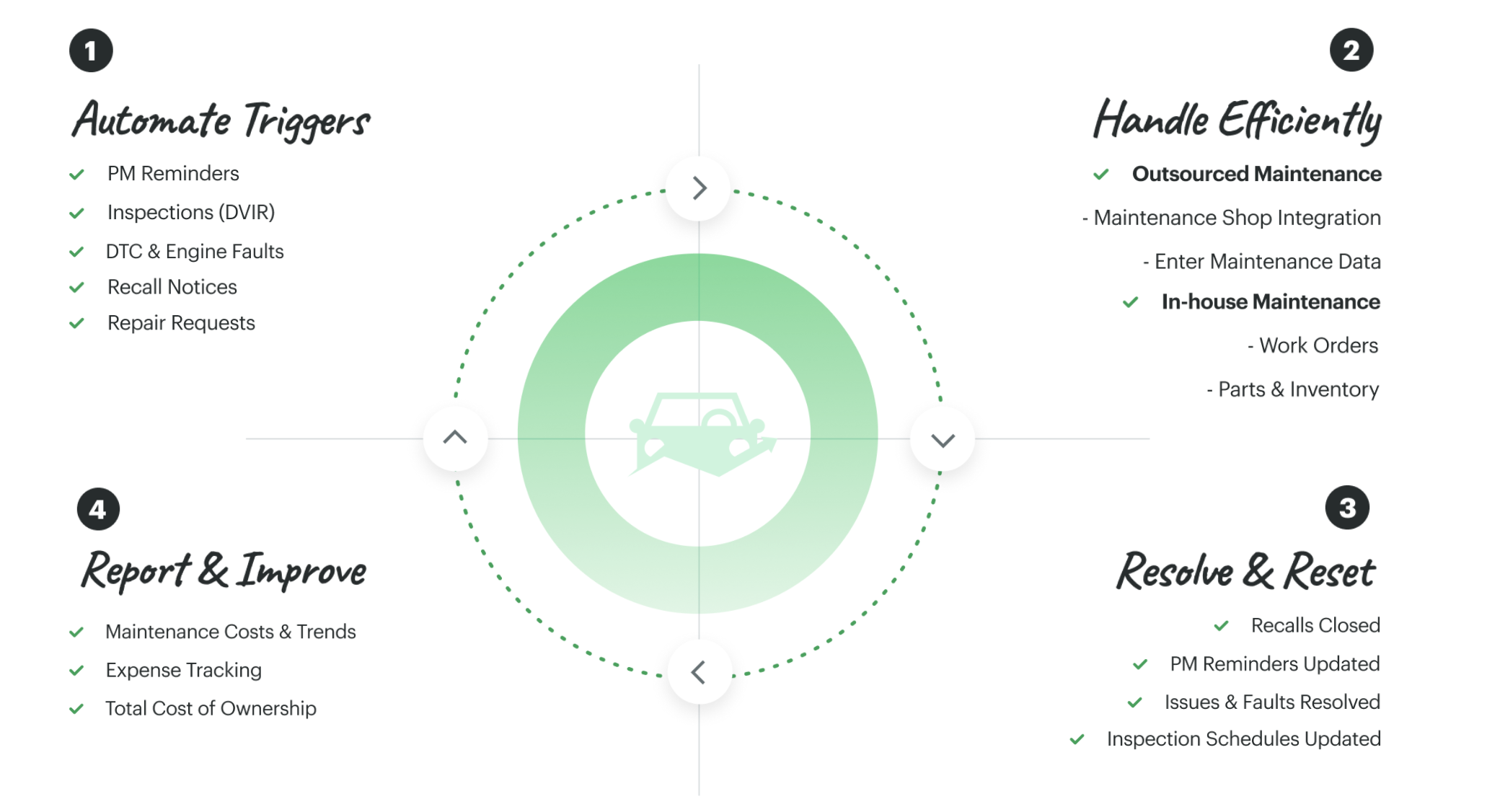

Creating preventive maintenance schedules in farm equipment maintenance software allows you to automate service reminders based on hour or odometer intervals. Managers can receive notifications for upcoming service tasks to ensure repairs are scheduled at an optimal time.

3. Uncover Issues With Inspections

As a farmer, you know how important safety is to your operation. Agricultural equipment must be properly maintained to avoid injury risks. Including equipment inspections in your team’s daily tasks is a great way to uncover issues and ensure all equipment is safe to operate.

Paper inspections may seem tedious, especially if you’re running a small operation. Farmers may pencil-whip from the driver’s seat to get started with their duties and overlook critical issues.

With farm equipment maintenance software, your team can complete inspections in a mobile app with just a few clicks. Instead of frustrating paperwork, they can conduct inspections quickly and add photos and comments to better communicate issues.

Electronic inspection apps also make it easy to tailor inspections to specialized assets. Managers can configure inspection forms to include items like safety measures or create their own for different types of assets.

4. Implement Efficient Maintenance Workflows

Farmers are tasked with staying on schedule to meet demand, things can go haywire when maintenance takes longer than expected. Increased downtime is usually due to a lack of communication.

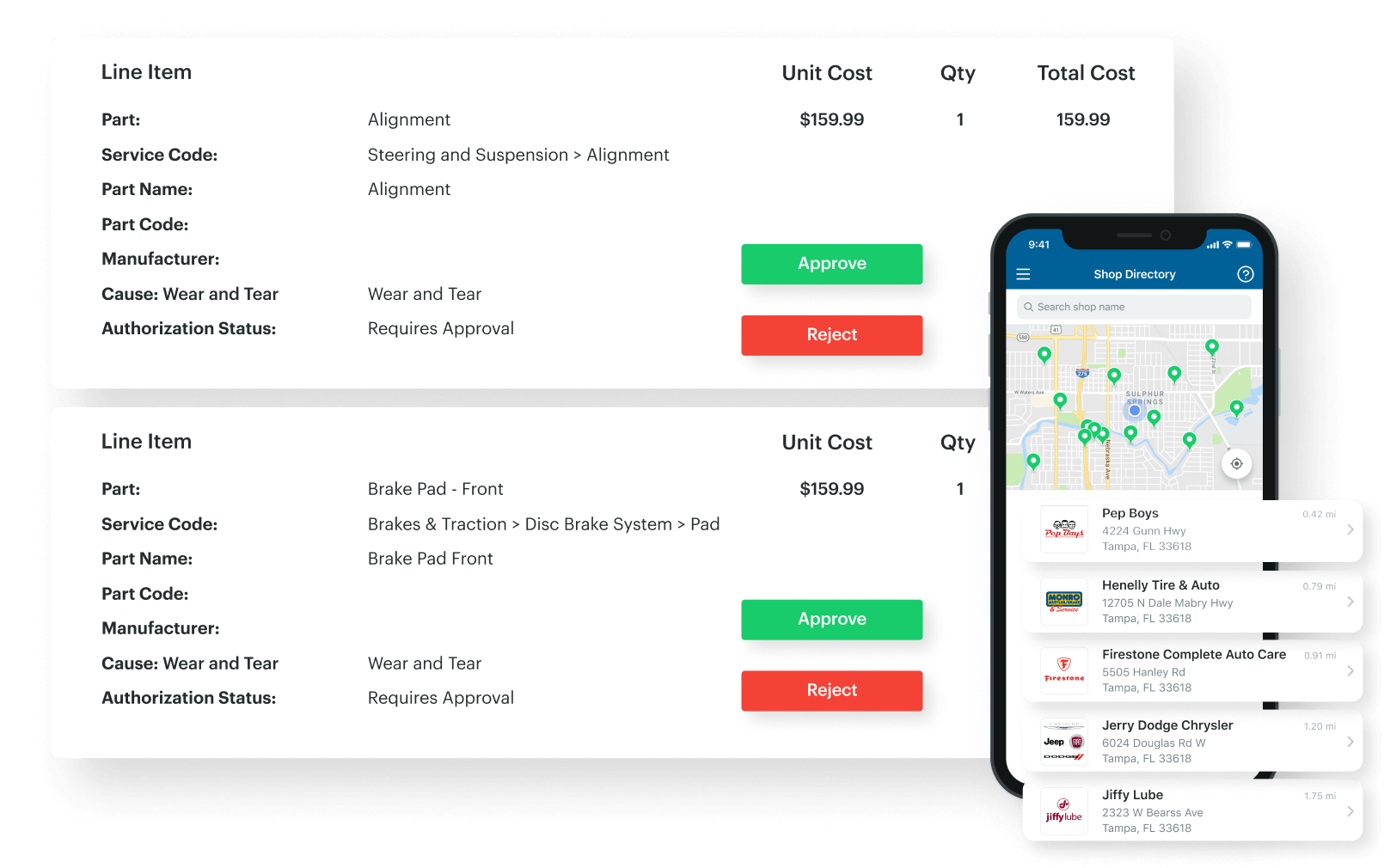

Whether your team is waiting on repair approvals or you’re waiting for progress updates about a certain tractor, communication gaps can cause inefficiencies and massive delays. Having a way to collaborate with your team in real time and monitor repair progress eliminates these bottlenecks and increases uptime.

Farm equipment maintenance management software allows you to track repairs in real time and stay connected to your team from anywhere. Managers can create digital work orders and assign them to technicians with just a few clicks.

Using mobile software to manage maintenance allows you to view real-time updates from the field and seamlessly collaborate with your team. Users can comment on issues, make suggestions and provide updates to keep everyone in the loop.

Choosing a software that allows unlimited users allows you to eliminate communication barriers across operations. By fostering collaboration within your team, you can improve communication and increase maintenance efficiency.

5. Leverage Fleet Reports to Monitor Fleet Health and Expenses

By centralizing farm equipment maintenance data in software, you’re able to analyze both real-time and historical data to improve your fleet. Managers can create configurable reports to visualize data including:

- Service history

- Operating costs

- Expense by asset

- Fault summaries

- Open issues

- Inspection failures

- Preventive maintenance compliance

With detailed maintenance and expense data, you have the insight to create efficiencies and ensure your assets stay profitable. Having all of your data in one place ensures you have the complete picture of your fleet’s health and performance and allows you to make informed decisions for the future.

Reap the benefits of increased uptime with Fleetio! Start your free trial or request a demo today!