For contractor and electrical fleets that want to be prepared to respond to natural disasters, preventive maintenance is the key to ensuring that your fleet is ready to go when you’re needed the most. What can you do to ensure your PM process is primed for natural disaster response?

One of the uncomfortable truths of working in contracting and utility is that you will likely find a lot of work in the aftermath of natural disasters. In the wake of Hurricane Ian, 42,000 linemen from multiple utility companies have been deployed to address Florida’s power outages alone, and more FEMA contractors will be deployed to address debris cleanup and other immediate needs as recovery moves forward.

For contracting fleets, electrician fleets and other companies that regularly take on natural disaster response – whether you deal with hurricanes, tornadoes, blizzards, flooding or any other kind of incidents – making sure that your vehicles are ready to go for whatever comes is one of the most important points of maintaining an effective and reputable operation. The key to true preparedness lies in constant, year-round preventive maintenance.

Scobee Powerline Construction often works alongside regional utility companies to restore service and rebuild power lines after weather related incidents. Based in Cameron, Missouri, in the center of the US, their fleet could be mobilized for any kind of weather conditions at any time of year.

“At the drop of a hat, we could get called on a storm, whether it’s a tornado, ice storm, or hurricane,” said John Blades, Scobee’s shop foreman. “We may have ten minutes’ notice to pack up and go.”

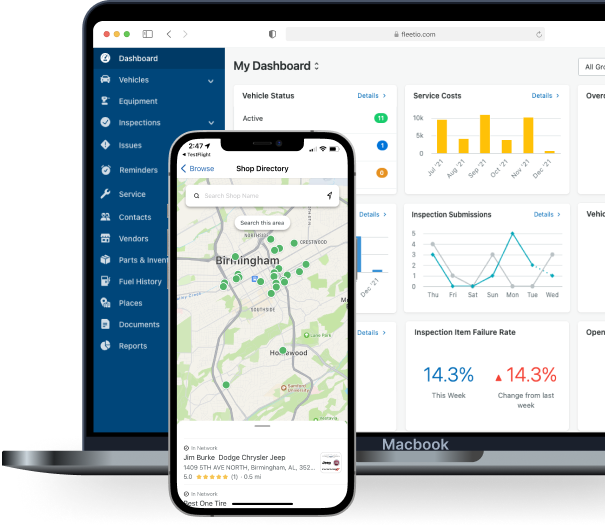

To stay prepared when disaster strikes, Scobee doubled down on their PM procedures, using fleet management software to keep a detailed log of services performed and customize maintenance schedules for their assets, as well as unify their two separate maintenance shops to keep everyone on the same page.

“[Software] makes my job easier, because everything is documented,” John said. “I rely on reminders so that I can schedule units to be brought to the shop and get the service done. You know the hours, the miles, when the service is due and what services have been done.”

Here are a few questions to ask yourself as you audit your preventive maintenance processes for emergency preparedness.

1. How thorough are your inspections?

Inspections are your first line of defense in preventive maintenance, as they allow you to look into the health of each of your assets on a day-to-day basis to help you catch potential issues before they take a vehicle out of commission. Ideally, all vehicles and heavy duty equipment should be thoroughly vetted for operation before and after each day’s work, and those records should be passed over to management to keep on file for logging and compliance purposes.

But if your processes currently entail paper forms for completing inspections, you could be opening yourself up to missing key indicators for potential problems. Paper forms can be cumbersome and time consuming for operators to complete, as well as easy to lose, which means you could be missing out on vital information you need to keep your assets serviced and ready to go in case of natural disasters.

Using a digital solution like PDFs, or better yet, a comprehensive fleet software, can be a lifesaver for emergency preparedness as well as compliance. Electronic driver vehicle inspection reports can be completed from a phone or tablet and immediately stored and sent to you as soon as they’re completed, and you can even automate work order generation as soon as a driver marks a failed inspection item, which means your vehicle gets in and out of the shop faster and will be ready to go whenever you need it most.

Prioritize preventive maintenance with Fleetio

Start your free trial2. Are you following a regular schedule for PM?

Inspections aren’t the only way to catch issues ahead of breakdowns. Making sure you follow OEM guidelines for preventive maintenance is an important facet of ensuring your vehicles will stay ready to go when you need them.

Good preventive maintenance is the determining factor of vehicle longevity – the more strictly you adhere to a PM schedule, the less likely you are to experience issues like blown tires or snapping belts on the job. Fleet maintenance software can help you assign a specific schedule to any of your assets and deliver notifications when it’s time for things like oil changes and new brake pads.

More importantly, you can use fleet management software to track each vehicle’s mileage from your telematics data, helping you keep an eye on utilization as you square away assets for disaster response and space out vehicle maintenance timelines so that you’re never down too many vehicles at one time.

3. Are you communicating efficiently with your shop?

One of the biggest barriers to a fast maintenance response is effective communications with technicians. Whether you’re working with a third-party provider or an in-house shop, fleet management software can help you streamline communications to minimize downtime for maintenance tasks.

Software can bridge the gap between techs and management by recording all information for work orders in app, which means techs can easily see reported issues and fleet managers can take a look at recommended services and their costs and approve them on the spot, with no excessive documentation or phone tag involved. Being able to submit quick approvals and communicate with shops in real time can drastically reduce a vehicle’s downtime, which means you’re more likely to have a full fleet in operation when you need to respond to natural disasters.

You’ll also want to make sure that you don’t put all of your eggs in one basket; maintain good relationships with multiple service providers so you’re never caught in a bind.

Want to stay better prepared to respond to natural disasters? Fleetio can help. Get your free trial or book a guided demo today!