Utility fleet employees rely on personal protective equipment (PPE) to help keep them safe at a jobsite. Poorly maintained PPE can increase the severity and likelihood of workplace injuries. Managers can help improve the effectiveness of PPE through tracking and monitoring their condition with digital, customizable inspections.

Importance of PPE in Utility

According to the 2022 Liberty Mutual Workplace Safety Index, "The top 10 causes of workplace injuries cost U.S. businesses more than $1 billion a week, with total injuries costing more than $58 billion every year." While roadway and off-road vehicle incidents cost a combined $4.98 billion yearly, the total dollar amount for injuries from simply lifting heavy objects incorrectly is a whopping $12.63 billion.

The utilities industry can be a high-risk environment to work in, and managers have to assess and account for all possible job hazards — both large and small. Ensuring your team’s PPE (whether provided by employer or employee) is effective and properly maintained and sanitized not only helps keep your fleet OSHA compliant, it helps improve safety and reduce the likelihood of serious or fatal injuries.

Communication and Historical Data Improve PPE Maintenance

Just like any other fleet asset, reusable PPE needs regular maintenance and upkeep for continued efficacy. A large part of PPE maintenance is knowing the signs of wear and tear, damage and equipment faults. Clearly communicating with your team about these signs and what to look for helps raise issues early and keeps employees from going into the field with ineffective PPE.

Because different PPE has different maintenance requirements — from cleaning and sanitizing to parts replacements — it can be difficult to keep up with upkeep. Fleets can use equipment inventory logs to help keep track of PPE, including: in-use and backup PPE inventory counts, to whom specific PPE is assigned and how long it’s been in use over a certain timespan. This information improves accountability among the team and can help fleets develop an equipment management program based on historical insights.

See how Fleetio’s customizable inspections can benefit your fleet

Start your free trialDigital Inspections Improve PPE Management

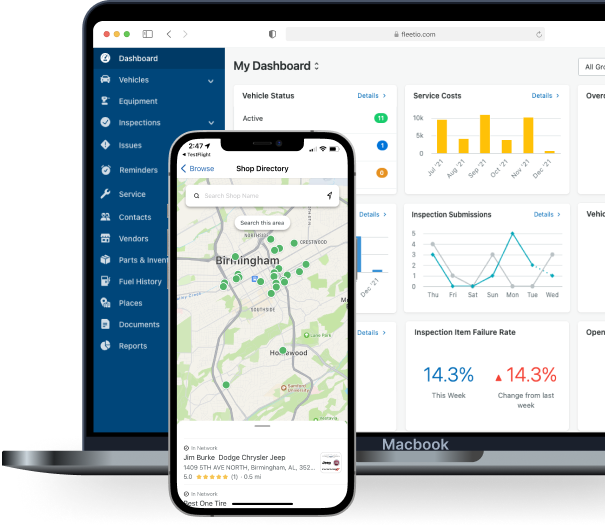

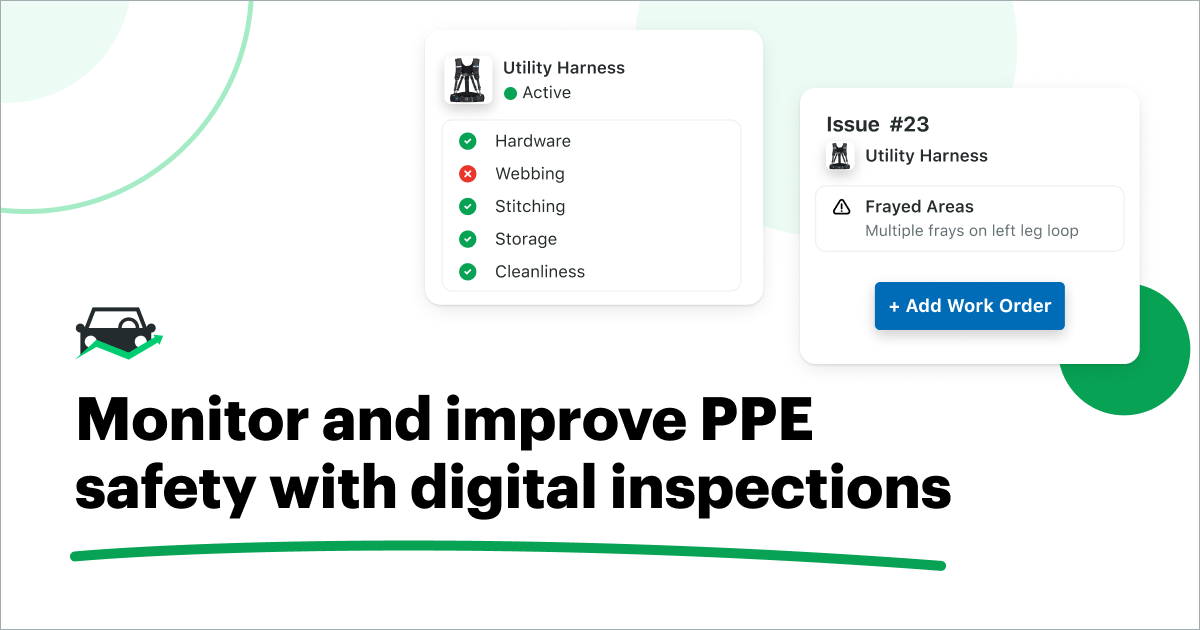

While fleet management software (FMS) is typically viewed as a tool for fleet and asset tracking, it’s not widely considered an equipment inventory software. FMS with a high level of customizability allows fleets to track and manage any fleet asset, from vehicles and heavy equipment to tools and, of course, PPE. When it comes to PPE maintenance management, digital inspections are a great first line of defense.

Digital inspections in FMS surface issues in real time to ensure maximum safety adherence. Managers and safety coordinators can customize inspections to meet the requirements of any PPE type. This allows fleets to create a pre-trip inspection checklist that employees can complete and submit through the software’s vehicle inspection app. Employees can attach images and documents or leave comments in inspections, improving communication around maintenance and faulty PPE. Furthermore, a failed inspection item notifies managers in real time so the issue can be addressed as soon as possible.

In addition to digital inspections, you can use fleet asset assignments so employees can check PPE in and out. Digital inspections and asset assignments provide increased accountability and clean historical data for improved insights into types of PPE failures, failure rate, replacement time frame, product quality and improper PM. Using this data, fleets can determine if, and what, changes they need to make to improve maintenance adherence, reduce PPE-related expenses and improve safety.

Find out how Fleetio’s customizable inspections can help keep your team equipped with safe, well maintained PPE. Start your free trial or request a personalized demo today!