At the start of a work day, drivers can be eager to get on the road and rush through or not complete pre-trip inspections. This can lead to increased vehicle failures and reactive vehicle maintenance. But what happens when drivers complete thorough inspections and report vehicle issues to management but are ignored?

In this post: 1. Impact on Safety 2. Increased Risk & Liability 3. Astronomical Costs

It is understandable that fleet managers may not act on every vehicle report. You are busy managing tens to thousands of vehicles, following an often tight budget and likely following a strict maintenance schedule. Choosing to ignore vehicle issues, however, can have a huge negative impact on the fleet.

Potential impacts on your fleet are as follows:

First of all, a poorly maintained asset can be unsafe for employees to operate. A vehicle may malfunction or unexpectedly breakdown and could result in an accident, potentially harming the driver or involved party and damaging the vehicle. For example, 43% of vehicle accidents are related to tire failure and could have been prevented with proper maintenance.

When a new fleet asset requires maintenance, sometimes the fleet manager mentality is that it’s a new asset, so it can’t be broken. Although maintenance issues are increasingly common with vehicle age, issues can still be present in new vehicles and should not be dismissed.

When employees are sent on the road with vehicles that are not compliant with vehicle regulations, management is impacting employee and vehicle safety and increasing the likelihood of an accident.

Secondly, pushing back vehicle issue repairs can be risky for fleet managers and the fleet as a whole. If an employee is involved in an accident, one of the parties — the driver or another involved party — may sue management for negligence. Fleet managers could be held liable for negligent maintenance of a vehicle, hiring or retention, lending of a vehicle or respondeat superior. What may have begun as a minor vehicle maintenance issue could result in a larger financial and legal issue for the fleet.

"Fleet managers could be held liable for negligent maintenance of a vehicle, hiring or retention, lending of a vehicle or respondeat superior."

Share on Twitter

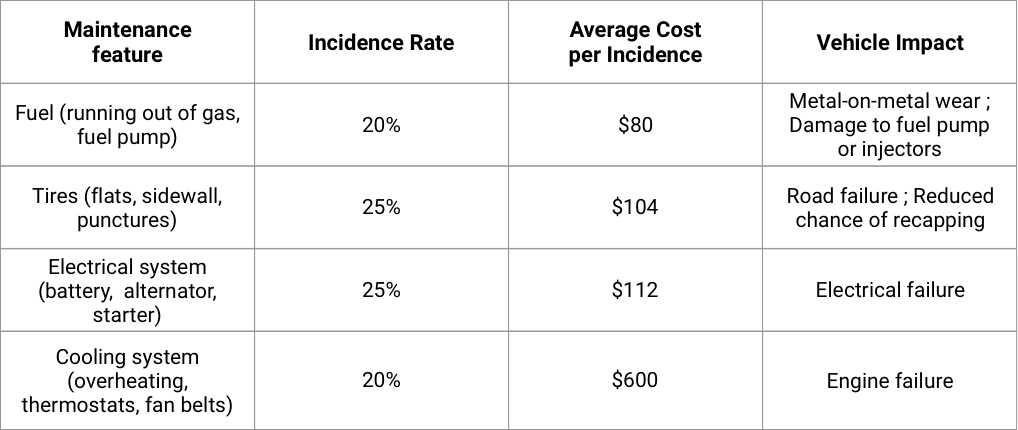

Although prolonging vehicle maintenance can save money in the short-term, the costs can be astronomical in the long term. Unexpected downtime can cost fleets an average of up to $800 per vehicle per day, which is significantly higher than the cost of the most common maintenance repairs as shown in the table below. In addition, fleets that receive inspection, repair and maintenance violations have to pay a median ticket price of $3,250.

When fleet vehicles are involved in accidents, the cost can be even more impactful. On average, an accident costs fleets $16,500. Fleet accidents that involve an injury can cost fleets $74,000 or that involve a fatality can cost $500,000. If the accident results in a court case, legal fees can increase the fleet bill further.

"Fleet accidents that involve an injury can cost fleets $74,000 or that involve a fatality can cost $500,000."

Share on Twitter

Short-term fleet benefits gained from prolonging vehicle maintenance clearly do not outweigh the impact on safety, the elevated risk or the high costs. When in doubt in regards to maintenance, play it safe and fix the vehicle issue.

Relevant blog posts: